Custom Cannabis Vape Hardware & Packaging for Brands That Expect More.

Vaporizers that hit every time, packaging that ships fast, prints clean, and passes compliance. We do it for brands that want to win on product experience.

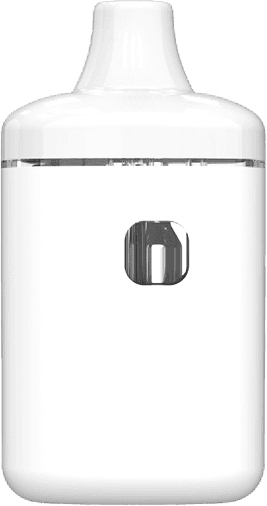

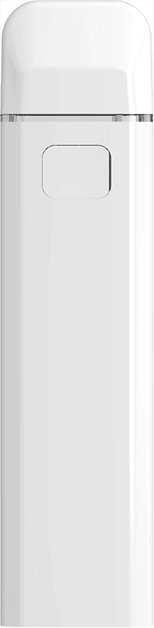

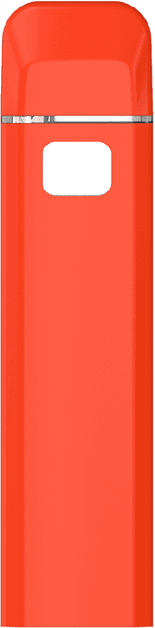

Custom-Tuned Vapes That Don’t Fail

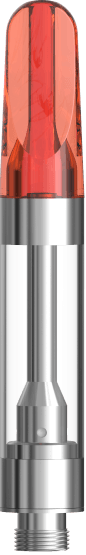

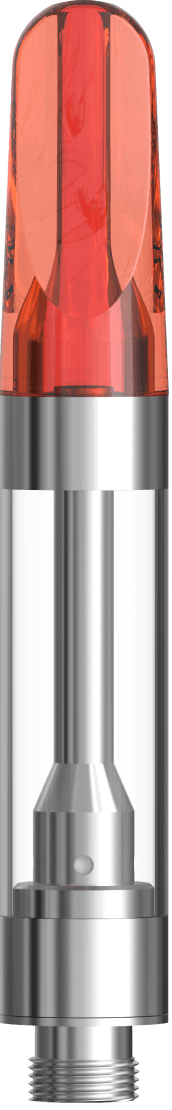

Powered by PrecisionFlow™ Atomizers

Most hardware only comes one way. Ours doesn’t.

Our PrecisionFlow™ atomizers are engineered for different oil types—from ultra-thin distillate to thick live rosin. Then we dial in airflow and temperature for the exact experience you want.

No clogs, no dry hits, no leaks. Just vapes that work—hit after hit.

Atomizer

Airflow

Temperature

Fast, accurate, and compliant packaging solutions

Seven years of iteration. Under two-week production timelines. Zero tolerance for errors.

We built our packaging system around what brands actually need: fast production, airtight quality control, and options that meet both compliance and sustainability standards.

Packaging

Categories

Proprietary child-resistant boxes in flat-packed or rigid formats, plus CR/Mylar bags with digital or roto-gravier printing.

510-thread batteries prepacked for retail with charger in custom boxes or Mylar bags, master cased and ready to ship to dispensaries.

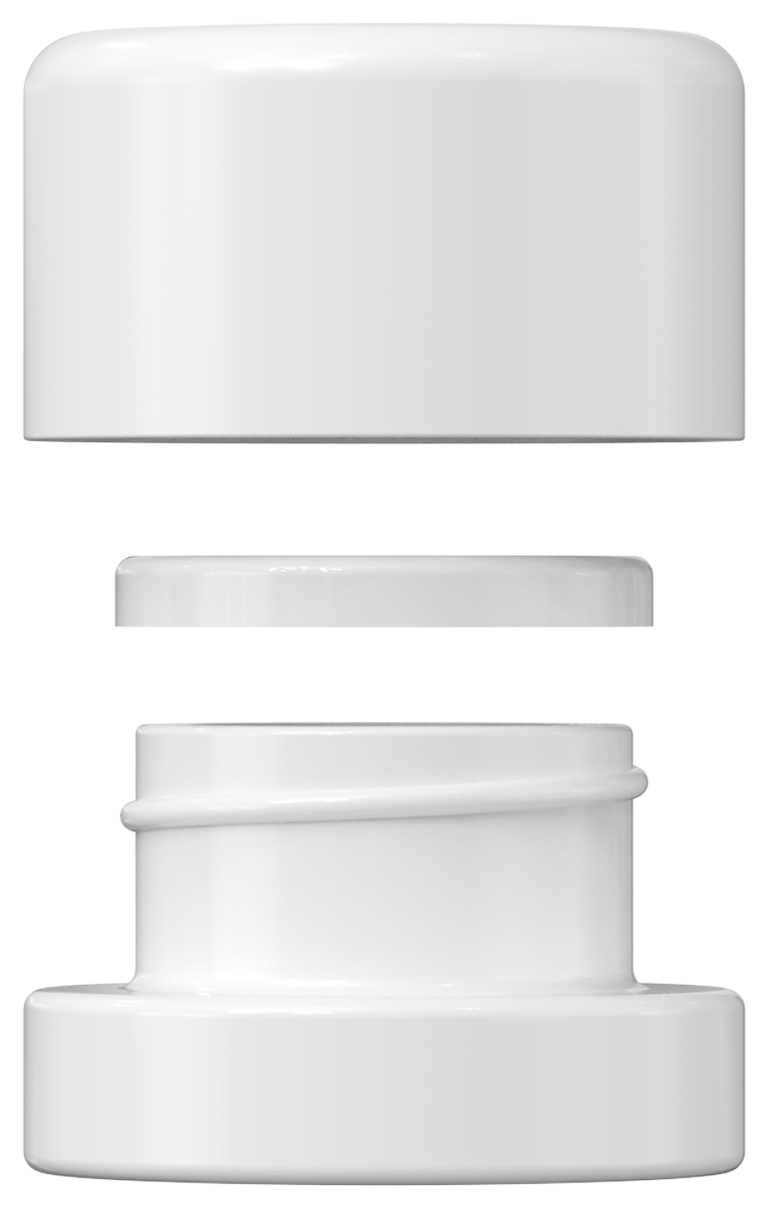

Custom jars from 5 mil to 15 mil in white, black, clear, or UV glass, paired with concentrate boxes built to fit any size and style.

Pop tops, screw tops, and jars in PET, PLA, or glass, fully customizable and stocked in both the US and China.

Mylar bags and glass jars in multiple sizes with custom finishes, labeling, and shelf-ready packaging.

Custom Mylar bags, chocolate bar boxes, and silicone molds built for compliance, food safety, and clean presentation.

Get in touch

with us

We can’t wait to hear from you. Reach out to our team for any inquiries and we’ll respond as soon as we can.